Meetup | How to Achieve Design for Manufacturing (DFM)

收起

活动内容收起

Since 2009, Chaihuo's parent company, Seeed studio, has been providing OEM production and processing services to its customers, undertaking small batch product verification to mass production. With over 10 years of experience in manufacturing, Seeed is backed by the rich supply chain resources in Shenzhen and a professional team (including account managers, project managers, procurement, production, manufacturing, engineering etc.), providing customers with a full range of production and processing services in over 700 projects. Seeed has always been committed to providing open-source hardware products for the global innovator community, and is always glad to share the experience of Open manufacturing in the past 10 years of projects.

柴火的母公司Seeed从2009年开始为客户提供OEM生产加工服务,承接小批量的验证到大批量量产,至今已经有10年的制造服务经验。背靠强大的深圳供应链资源以及拥有专业的项目团队包含客户经理,项目经理,采购,生管,制造工程等为客户提供全套的生产加工服务,至今已经为700多个项目提供了服务。Seeed一直致力服务于开源硬件产品,也非常乐于分享在这10年来服务过的众多项目过程中的关于Open manufacturing的经验。

In order for the global maker community to better understand our manufacturing process and environment, we will invite Seeed’s OEM senior project engineer, Yao Zhibin, and Account Manager, Mandy Xiang, to conduct a sharing on “Open Source Manufacturing” here at Chaihuo x.factory. On the evening of September 18 (next Wednesday), these two experts will be sharing on the most important part of the production service process: Design for Manufacturing (DFM).

为了更好地让国际社区深度了解制造生态和细节,接下来,我们会特别邀请Seeed OEM资深项目工程师姚志彬以及客户经理向曼在柴火发起“开源制造”分享。9月18日晚(下周三),两位专家为会大家分享在生产服务过程中最为重要的一个环节:可制造性设计DFM(Design for Manufacturing)。

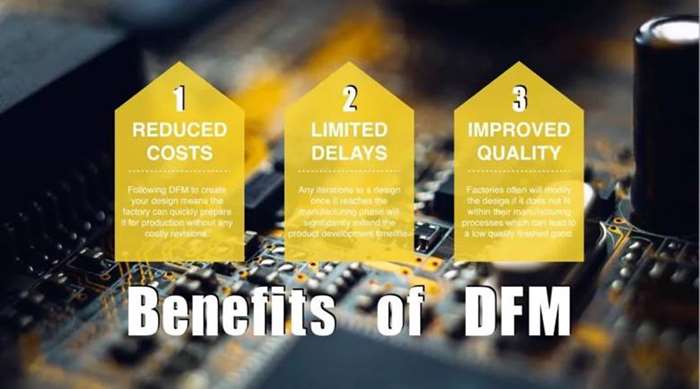

DFM is not just any simple technology. In a sense, it is a technique that incorporates design-based thinking into all aspects of the product making process, and its role is to improve the manufacturing process of the product. Today's DFM is the core technology of modern engineering, as design and manufacturing are the two most crucial aspects of a product’s life cycle. Concurrent engineering, also known as simultaneous engineering, is a method of designing and developing products, in which the different stages run simultaneously and the manufacturability and assemblability of the product are assessed from the initial design stage. Since the key to concurrent engineering is the technical analysis, manufacturing rationality evaluation and recommendations for design improvement, DFM is the most important support tool for this process.

DFM,不是单纯的一项技术,从某种意义上,它更是一种设计思维,包含在产品实现的各个环节中。DFM作用就是改进产品的制造工艺性。当今的DFM是并行工程的核心技术,因为设计与制造是产品生命周期中最重要的两个环节,并行工程就是在开始设计时就要考虑产品的可制造性和可装配性等因素。所以DFM又是并行工程中最重要的支持工具。它的关键是设计信息的工艺性分析、制造合理性评价和改进设计的建议。

For the upcoming meetup, the two experts will share the following contents:

1. Seeed’s OEM Service Introduction

2. About DFM (Design for Manufacturing): What is DFM? Why should you do DFM?

3. How does Seeed do our DFM service?

4. Case Study: If your project has a demand for DFM and the project can be shared on-site, please send the design file to us by email, we will do a professional DFM analysis for FREE and explain it on the spot on the day of the event.

本次分享的具体内容如下:

1. Seeed OEM服务介绍

2. 讲讲DFM(Design for Manufacturing):什么是DFM?为什么要做DFM?

3. Seeed是如何做DFM的?

4.案例分析:如果您的项目对DFM有需求,并且项目可在现场分享,请通过邮件将设计文件发送到,我们会为您做专业的DFM分析并在活动当天工程师会进行当场讲解。

Zhibin Yao, Seeed’s Senior Project Engineer

姚智彬,Seeed资深项目工程师

Graduated from Wuhan University of Technology in 2013. Joined Seeed in September 2017, senior project engineer; mainly responsible for OEM product quotation, DFM, alternative material selection and verification, NPI product process design, new product production exception processing and process optimization, continuous follow-up optimization of mass production products. Previously, he worked for a car electronics manufacturing company;

2013年毕业于武汉理工大学。2017年8月加入Seeed,资深项目工程师;主要负责OEM产品报价,DFM,替代料选型和验证,NPI产品流程设计,新产品生产异常处理及制程优化,量产产品的持续跟进优化等。此前,他任职于一家的汽车电子产品制造公司;

Mandy Xiang, OEM Account Manager at Seeed

向曼 Seeed OEM部客户经理

Graduated in 2009, she worked as a Process Quality Engineer and PM in the Foxconn Technology Group's FIH PLX and IGSBG business groups. Joined Seeed in March 2014 as an account manager in the OEM department with 10 years of manufacturing experience. So far, she has been responsible for batch production orders for more than 50 customer products, and continues to provide professional OEM customized services with the Seeed manufacturing team.

2009年毕业,之前于富士康科技集团FIH PLX以及IGSBG事业群先后任职制程品质工程师以及PM。2014年3月加入Seeed任职于OEM部门做客户经理,10年制造服务经验。迄今负责过50多个客户产品批量量产订单,和Seeed制造团队一起持续为客户提供专业的OEM订制服务。

Event Details

Time: September 18th (Wednesday) 19:30-21:00

Fee: Free, limited slots available

Number of people: 30 people

Venue: Chaihuo x.factory, B608, Design Commune, Vanke Cloud City, Nanshan District, Shenzhen

Registration: Click “Read more” at the end of this post to register asap.

活动详情

时间:9月18日(周三)19:30-21:00

费用:免费限额开放

人数:30人

场地: 深圳南山区打石二路万科云设计公社B608柴火创客空间

报名:文末点击“阅读原文”即可快速报名

活动标签

您还可能感兴趣

您有任何问题,在这里提问!

全部讨论

活动主办方更多

柴火创客空间

2011年,柴火创客空间由深圳矽递科技股份有限公司创始人潘昊成立,寓意“众人拾柴火焰高”。2015年,李克强总理到访柴火并成为柴火荣誉会员。柴火是深圳第一家创客空间,自成立以来,一直在推动创客文化的传播和创新创业的促进,成为海内外创客对接深圳产业资源的桥头堡。定位“深度服务产业创新升级的国际化双创平台”,柴火致力聚合国际创新人才,为创新制作者(Maker)提供自由开放的协作环境,鼓励跨界的交流,促进创意的落地以至产品化。同时,立足传统产业的创新需求,搭建创客与产业协作对接的平台,推动全球创客社区的创新解决方案嫁接到本地产业链,推动产业创新升级。目前,除了深圳本部,柴火已在河北石家庄设立了分部,聚焦“科技生态”主题,引入国际创新方案,垂直服务当地企业对科技创新升级需求。